Top Unheading Valves

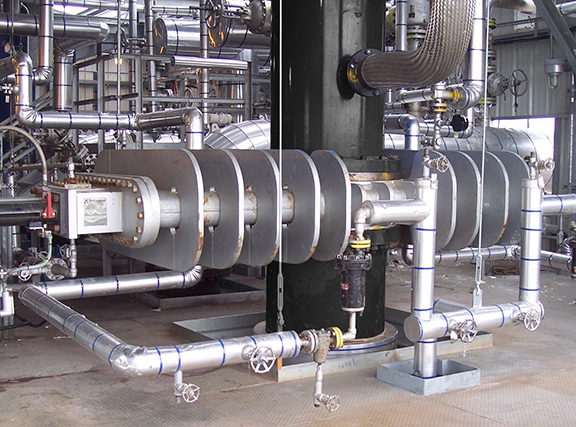

Coke Drum Top Unheading Valve

The DeltaValve coke drum top unheading valve permanently connects to the top flange of the coke drum. With this device, top drum unheading can now be safely accomplished with the push of a single button from a remote location, removing operators from the cutting deck and protecting them from potential coke drum eruptions and top head blow-outs.

Key Advantages

- Proven technology

- Fully automated

- Part of a totally enclosed system

- Low maintenance

- Steam purged

- Single button operation

- Quick, safe unheading

Physical/Technical Attributes

Top Unheading Valve

| Design | Per ASME section VIII Div.1 |

|---|---|

| Construction | Cast |

| Metallurgy | ASME SA387 Gr5 (optional Gr22) ASME SA217 GrC5 |

| Dimensions - 30" | 252”L x 59”W x 22”H 16.2” face to face |

| Actuation | Hydraulic or electric |

| Interlocks / Controls / HPU | Engineered to plant specifications |

| Positive Lockout | Removable lock-out pin |

| Mounting | Direct bolt to drum top flange |

| Purge Media | Steam |

| Function | Open/close |

| Valve Size | 30 and 36 inch |

| Temperature Rating | Seats/Gate (process): 900oF (482oC) Body (steam): 450oF (232oC) MAWP temperature/pressure curves available |

| Pressure Rating | 105 psig (723.4 kPa) @ 900oF (482oC) |