CenterFeed® Injection Device

Side Feed Entry, Bottom Feed Results

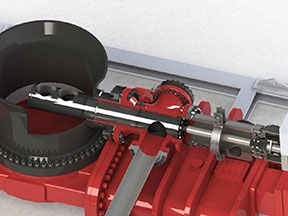

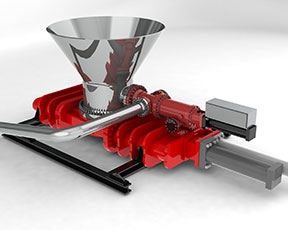

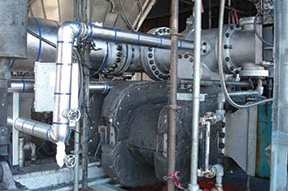

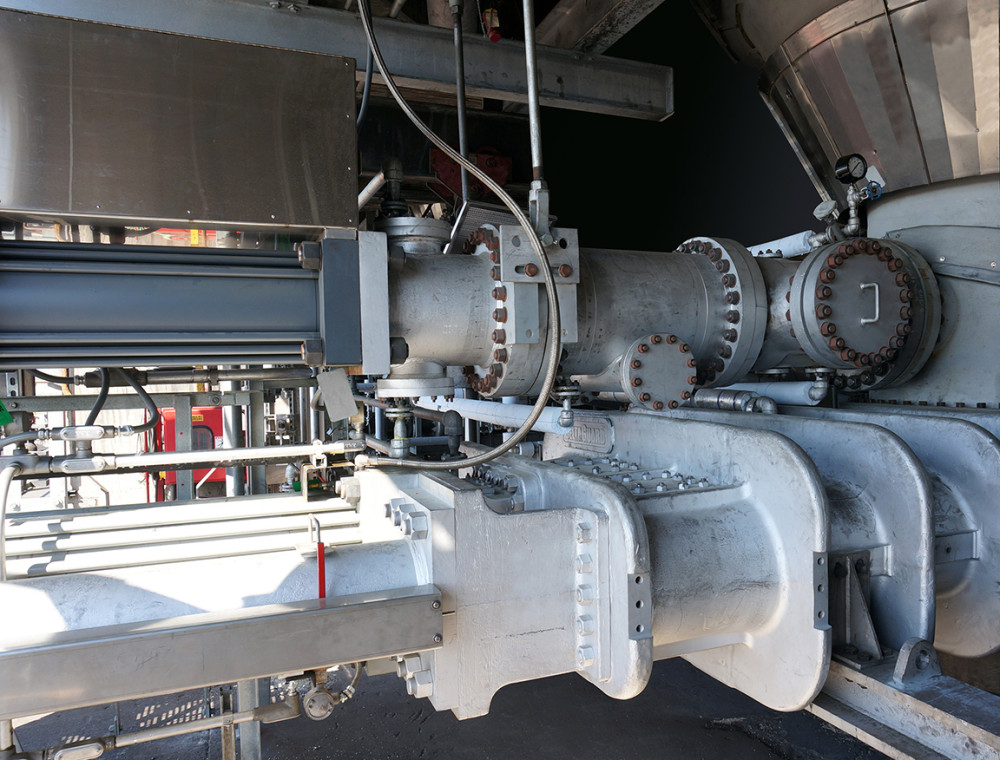

DeltaValve’s CenterFeed® Injection Device was developed to combine the benefits of traditional bottom center feed with the advantages of side-feed entry. This technology creates uniform, centered flow channels which reduce the rate of temperature change at the drum wall, reducing overall coke drum stresses, top head blowouts, and premature drum failure.

Key Advantages

- Facilitates side feed drum entry

- Flow channeling up the center of the coke drum

- Reduced coke drum stress, warping, and bulging

- Reduced hot-spots, top head blowouts, and eruptions

Physical/Technical Attributes

CenterFeed® Injection Device

| Construction | Cast/fabricated |

|---|---|

| Metallurgy | Body: ASME SA217 GrC12 Bonnet: ASME SA387 Gr22 |

| Sizes | 6—18 inches (in 2 inch increments) |

| Weight | 8000—25000 lbs. |

| Actuation | Hydraulic, electro-hydraulic, electric |

| Interlocks / Controls / HPU | Engineered to plant specifications |

| Positive Lockout | Lock pin (hydraulics), Gearbox lock pin (electric) |

| Mounting | Bolted to transition spool inlet feed line, spring-can supported |

| Purge Media | Steam |

| Function | Open/closed |

| Temp/Pressure Rating | 950OF @ 300 psi (18”) 950OF @ 380 psi (16” and smaller) |